You are here:

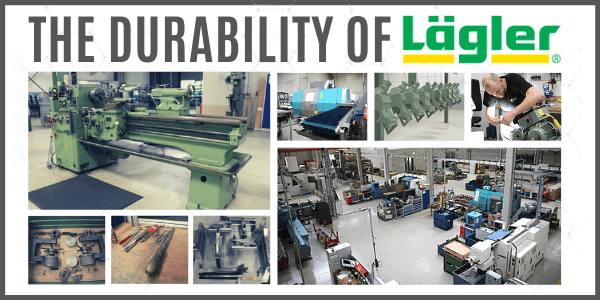

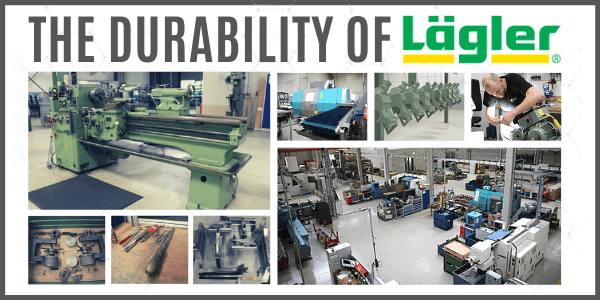

We take enormous pride in the longevity of the machines we produce. Our equipment is intended to last decade after decade- as a matter of fact, the first HUMMEL® ever built in 1969 is still running today! This durability is achieved directly from our manufacturing processes and standards, starting with the production equipment itself.

Today, LÄGLER boasts state-of-the-art CNC equipment which is used to build more than 85% of our machine parts right in house. What may be interesting to know though is that we are also still using machines that were constructed in the 1960s to educate apprentices who come to work in our factory. Our apprenticeship program is 3 ½ years long, and participants start out doing the work with hand tools, then move on to manual milling, turning, and cutting tools (also from the 60s) before they start to use the CNC equipment.

In addition to using tools that are proven to stand the test of time, we also have our own tool shop with proprietary equipment that we develop to build and check all assembly devices used in production. For example, we make molds for in-house casting and have over 100 pressing tools for sheet metal. When it comes to the handful of items produced outside of our factory, we still produce and maintain tools that are sent to long-term suppliers for use in manufacturing, such as large housing molds for aluminum die casting.

No matter how small the part or tool used in production, it is checked for quality control on a regular basis, from the power tools for the right torque to measuring devices like calipers. We are checking for durability even when it comes down to producing that #TeamGreen color we are known for- since 2003, we have been using a long-lasting, environmental friendly powder paint coating process that is done in house and meant to last.

Before a LÄGLER product ends up in your hands, on your job site, you can be confident that every part and every machine has gone through a multi-step rigorous testing process and has even had a test run on German white oak. Whether we’re using 50+ year old tools or the latest CNC equipment, you can be confident that your LÄGLER machine will be up for any job, time after time.

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.