You are here:

A goal for every contractor’s business should be to minimize effort and time on-site while maximizing quality results and profits. Wood floor sanding is

hard work, but that doesn’t mean it can’t be smart work, too.

With a few smart changes to conventional wisdom, hard work can become easier and it can produce better results. The keys to success lie in the mix of sanding

machines, abrasives and grit sequences used on the job.

Maximum flatness should be the focus on every sanding job. The quality of machines a contractor uses matters, but sanding machines no more make a floor

than a camera makes a photograph or a race car wins a race. The person using the right machines for the job, and with the right knowledge, skill and

touch, is the real difference-maker.

Conventional sanding methods mean using a big machine and edger. A buffer sometimes is used for fine sanding. With this method, the big machine is used

for sanding 90 percent of a room’s field, and it is where 75 percent of the sanding time is spent. The edger does the rest of the heavy lifting.

The new-school sanding method adds a multidisc sander to take flatness to a new level. The multidisc can be used for fine sanding but, unlike a buffer,

packs enough bite to carry some of the big machine and edger’s workloads, too.

Using a multidisc sander shifts how much energy and time a sanding professional spends on each machine. It accounts for 40 percent of sanding time on a

typical job. It reduces time spent on a big machine by 33 percent, and time spent on an edger by 60 percent. That leads to less wear and tear on the

body of the professional.

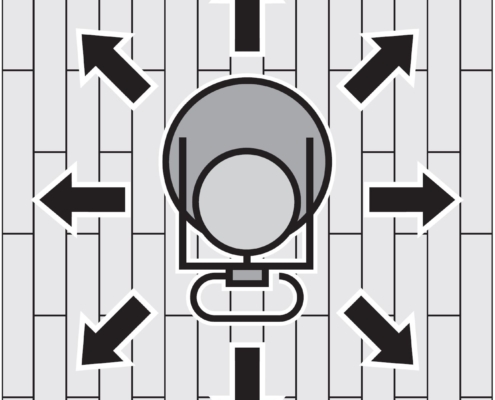

A multidisc can be run in all directions. It reduces risk of common issues like chatter and dishout. It also handles multispecies floors much better than

the big machine.

The industry’s leading craftsmen are turning to the multidisc as a game-changer, a machine they can use to set their floors apart from their competition’s.

Quality abrasives are crucial role players on any sanding job. If the abrasives are not up to standard, the sanding results also will be less satisfying

than expected, no matter the quality of machines being used.

The materials used in making abrasives affect sanding rates and how many square feet of life a professional gets out of them. Inexpensively produced abrasives

have shorter service life and need more frequent changing. The minerals used in inexpensive abrasives do not perform as aggressively, leading to more

time spent in the sanding process.

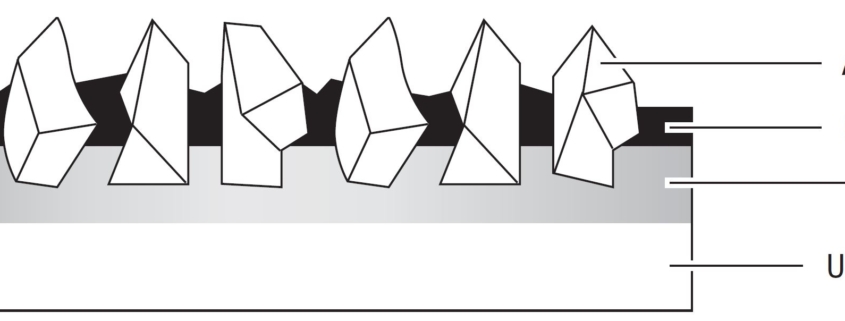

Synthetic bonds are primarily used in today’s abrasives. They offer higher temperature stability, higher abrasion resistance, and better adhesion to the

abrasive grit and underlayment than previous bindings.

Zirconia and ceramic abrasives offer advantages compared to silicon carbide and aluminum oxide (corundum) abrasives. Ceramic and zirconia have higher sanding

rates and longer service life that equals less frequent changing. Their longer service life requires less inventory be kept on hand, and less storage

space be used in the trailer, van or shop.

Zirconia abrasives are more expensive than silicon carbide and aluminum oxide, but due to its advantages, it offers a better cost-per-square-foot value.

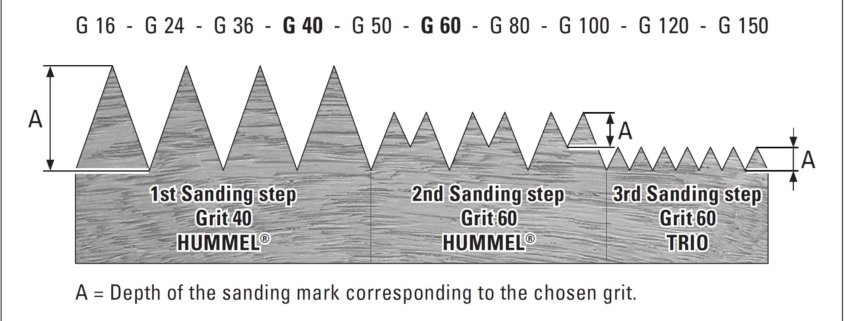

Start a sanding job with as coarse a grit as necessary, but as fine a grit as possible. It’s important to correctly choose the starting grit and to follow

the correct grit sequence, or lost time and money will add up while trying to correct sanding mistakes.

Coarse abrasives are more expensive than fine abrasives. For floors that require an exceptionally coarse start, such as 16 or 24 grit, save money by using

abrasives with less expensive minerals. Use silicon carbide sanding discs on the edger, multidisc and buffer, and aluminum oxide belts on the big machine.

Save higher-quality abrasives (zirconia) for intermediate sanding steps. That is from grits 36 to 80 on the big machine, and as high as 150 on the edger

and multidisc. Silicon carbide sanding screens work well on a multidisc sander and buffer, starting at 60 grit.

No more than one grit should be skipped when using a big machine or edger. When fine sanding with a multidisc sander, do not skip any grit numbers. Fine

grits remove a low volume of wood material from the previous sanding step, and a skipped grit leaves marks too coarse to adequately be removed.

Correct selection of the grit sequence is even more important for oiled surfaces than for finished floors. That’s especially worth paying attention to

since, in recent years, natural oils have become more popular with homeowners. Homeowners also are showing increasing interest in interior design and

open-space floorplans that allow larger amounts of natural light.

That highlights the need for sanding professionals who can produce the flattest, most flawless floors. Being capable of producing top-tier results while

minimizing energy, time and costs of materials on the job is essential to a contractor’s success.

Note: A version of this post appears in the June/July 2017 issue of Hardwood Floors Magazine.

Karleugen Lägler is director of Lägler GmbH. With 50 years in the floor sander manufacturing company, he is the world’s leading floor sanding expert. Lägler GmbH offers free downloads of its “Sanding of Wooden Floors” manual in six languages at laegler.com.

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.