You are here:

There are two approaches to floor sanding: guesswork and science.

Guesswork creates variables and challenges in sanding jobs that aren’t there. It causes the professional to change his or her approach from job to job,

species to species, and floor pattern to pattern. It produces results that vary.

The science of sanding is a proven process a professional can learn and use on each job, regardless of species, board widths, and installation pattern.

It produces consistent, quality results.

Quality is everything, if you’re trying to build a strong business on good work. That goes for your skills, machines, customer service, abrasives and the

other details. If you’re off-target in just one of those key areas, word on the street will bite you in the dust bag, whether you know it or not.

We talk about training and boosting your skills often on this blog, especially about Lägler’s Premium Sanding Technology (PST) class. Of course, we get into machine quality every day, too, talking about the standards Lägler holds itself to or just by posting photos of

Lägler’s craftsmen on Instagram quietly going about the business of hand-building and testing its machines.

It’s time to talk more about the ripple effect of choosing quality, especially with abrasives.

Quality abrasives play a super-important role. Like with anything, you get what you pay for. Pay for cheap products, get cheap results.

You probably tell homeowners that. And you often see the problems caused by hacks, right? A homeowner calls you in to fix the disaster a “professional”

made of their floor. It was the low bidder they’d hired for the initial job, focusing only on the short-term pain of the money they were spending.

Now they are losing sleep, stressing the expense and headaches of the shoddy work they got from the contractor from hell.

They are painfully figuring out they’ve got to pay you what they should have stepped up to pay in the first place, just to fix the mess. That’s on top

of the money they already spent and the worry it caused them. Cheap quickly turned into way more expensive.

The same goes for any business that relies on quality ingredients to put out quality products or services it sells. A restaurant that goes cheap to save

a buck is short-sighted. It loses business in the long run because it’s worried about the cost of, say, a case of burger patties. The owner of that

restaurant probably isn’t connecting bad Yelp reviews to one purchase like which meat to buy.

But it isn’t just the meat. It’s the domino effect of that mindset that leads to going cheap on one thing after another. That restaurant owner doesn’t

invest in the other ingredients, either. Or replace the dirty or torn seats in the joint, or keep its restrooms clean, or care all that much when a

jaded employee doesn’t give customers a hello or smile or quality experience. Downward spiral.

For a true flooring pro – a craftsman – pride in quality work is at the top of the list. The good kind of word on the street makes the rounds and builds

the business like it’s got its own motor. Do good work, get good work.

The materials used in making abrasives affect sanding rates and how many square feet of life a professional gets out of them. Inexpensively produced abrasives

have shorter service life and need more frequent changing. The minerals used in inexpensive abrasives do not perform as aggressively, leading to more

time spent in the sanding process.

In the end, the additional costs of buying, storing, and transporting a larger quantity of lower-quality abrasives, plus having to spend more time sanding

with them makes investing in quality upfront a better value. (Sounds like that thrifty homeowner in the example above, right?)

In fact, the science of sanding means little without using the right abrasives for the right situations. A highly skilled race-car driver who has a fine-tuned

car can do little with it if the wrong tires are on it.

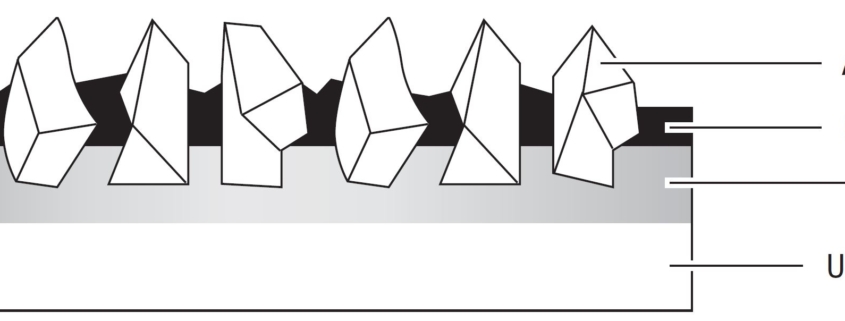

For wood floor sanding abrasives, the minerals, underlayment and adhesive are difference-makers. The types of underlayment (paper or cloth) and minerals

(silicon carbide, ceramic, aluminum oxide, and zirconia) needed depend on the intended use.

Grit sequence is a key factor in the floor sanding process. It’s essential to follow the steps, like shifting properly through a race car’s gears. The

driver doesn’t get ahead by skipping gears. Instead, he bogs down his momentum.

Unlike in a car, proper grit sequence allows for skipping one grit, but only one. If a professional jumps two or more grits in the sequence, the scratches

from the previous grit will not be adequately removed. It will cost more effort, time, and abrasives to redo the work.

The first sanding step should be done with as coarse a grit as necessary, but as fine a grit as possible. That’s where the variable enters this science

of sanding. The professional must use his experience to recognize if a floor’s condition calls for an especially coarse grit to start.

For example, if it shows severe cupping or is coated with thick lacquer. The starting grit will help to determine the ending grit to be used. Everything

in between follows the steps of the process.

The science of sanding can be learned. A sanding professional can bank on its predictable, craftsman-quality results. No guesswork needed. Clients might

think it’s magic. It’s OK to leave them guessing.

Quality customers know when they are dealing with quality professionals. When they hire someone to sand and refinish their floor, they are investing a

good chunk into their home. They want to feel great about that. They want to know what they get back for their trust in you will be worth a grit when

the job is done.

Choosing quality is everything.

Learn more about the best ways to boost your floor sanding game. Learn it from Karl Lägler, the man who wrote the book on that game, by downloading the

free “Sanding of Wooden Floors” manual online from Lägler.

How to Minimize Sanding Efforts + Maximize Business Profits

Lägler North America, a division of Palo Duro Hardwoods, is the North American distributor of machines and parts manufactured by Eugen Lägler GmbH in Germany. We are North America’s machine repair center, and offer Lägler’s one-day Premium Sanding Technology (PST®) certification course.

Copyright © 2020 Lägler North America. All Rights Reserved.